Olympus 38DL Plus Ultrasonic Thickness Gauge

The 38DL PLUS is an innovative instrument that signals a new era in ultrasonic thickness gauging. Ideally suited for almost every ultrasonic thickness application, this handheld thickness gauge is fully compatible with a full line of dual and single element transducers. The versatile 38DL PLUS can be used in applications ranging from wall thinning measurements of internally corroded pipes with dual element probes to very precise thickness measurements of thin or multilayer materials with single element transducers.

Features:

Dual and single element transducer compatibility

Wide thickness range: 0.08 mm (0.003 in.) to 635 mm (25 in.) depending on material and transducer selection

Corrosion thickness gaging with dual element transducers

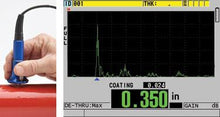

THRU-COAT® and Echo-to-Echo measurements on painted and coated surfaces

Internal Oxide/Scale software option

Standard resolution of 0.01 mm or 0.001 in. for all transducers

High Resolution software option of 0.001 mm or 0.0001 in. with single element transducers 2.25 MHz to 30 MHz

Multilayer software option for measurements of up to four layers simultaneously

High Penetration software option for attenuating materials such as fiberglass, rubber and thick casting

Thickness, Velocity, and time-of-flight measurements

Differential mode and Reduction Rate mode

Time-based B-scan mode; 10,000 reviewable readings per scan

Olympus High Dynamic Gain technology with digital filters

V-Path Builder for custom V-path compensation

| Dual element transducer measurement mode | Time interval from a precision delay after the excitation pulse to the first echo |

| THRU-COAT® measurement | Measurement of true metal and coating thicknesses with a single back-wall echo (with D7906-SM and D7908 transducers) |

| Thru-Paint Echo-to-Echo | Time interval between two successive back-wall echoes to eliminate paint or coating thickness |

| Single element transducer measurement modes | Mode 1: Time interval between the excitation pulse and the first back-wall echo Mode 2: Time interval between the delay line echo and the first back-wall echo (with delay or immersion transducers) Mode 3: Time interval between successive back-wall echoes following the first interface echo after the excitation pulse (with delay line or immersion transducers) Oxide: optional Multilayer mode: optional |

| Thickness range | 0.080 mm to 635.00 mm (0.003 in. to 25.000 in.) depending on material, transducer surface conditions, temperature, and selected configuration |

| Material velocity range | 0.508 mm/μs to 13.998 mm/μs (0.020 in./μs to 0.551 in./μs) |

| Resolution (selectable) | Low: 0.1 mm (0.01 in.) Standard: 0.01 mm (0.001 in.) High Resolution (optional): 0.001 mm (0.0001 in.) |

| Transducer frequency range | Standard: 2.0 MHz to 30 MHz (-3 dB) High Penetration (optional): 0.50 MHz to 30 MHz (-3 dB) |

| Operating temperature range | -10 °C to 50 °C (14 °F to 122 °F) |

| Keypad | Sealed, color-coded keypad with tactile and audible feedback |

| Case | Impact-resistant and water-resistant, gasketed case with sealed connectors. Designed for IP67. |

| Dimensions (W x H x D) | Overall: 125 mm x 211 mm x 46 mm (4.92 in. x 8.31 in. x 1.82 in.) |

| Weight | 0.814 kg (1.80 lb) |

| Power supply | AC/DC adaptor, 24 V; lithium-ion battery 23.760 Wh; or 4 AA auxiliary batteries |

| Battery life, lithium-ion | Operating time: minimum 12.6 h, 14 h typical, 14.7 h maximum Fast charge: 2 h to 3 h |

| Standards | Designed for EN15317 |